CMYK colour gamut’s, digital presses and brand and special colours

Not a snappy title but it covers the issue I wish to discuss.

Not a snappy title but it covers the issue I wish to discuss.

Many printing markets, such as packaging, point of sale and areas of the commercial sectors, due to the demands of the client, need to match brand, Pantone and other colours very accurately, often within De2000 2.5. This is a very tight tolerance.

Analogue printing in CMYK; offset litho, flexo, gravure, cannot match many of these colours using an CMYK conversion, due to the relatively limited colour gamut of their CMYK inks. So to is common practise to print these colours as an extra colour, involving an extra plate and printing unit per colour, in order to match the De2000 tolerances required.

So, as the move to digital printing methods takes place in these markets, driven by cost, shorter runs, personalisation, the need to reduce inventory etc., how do the many differing digital printing technologies cope with this requirement?

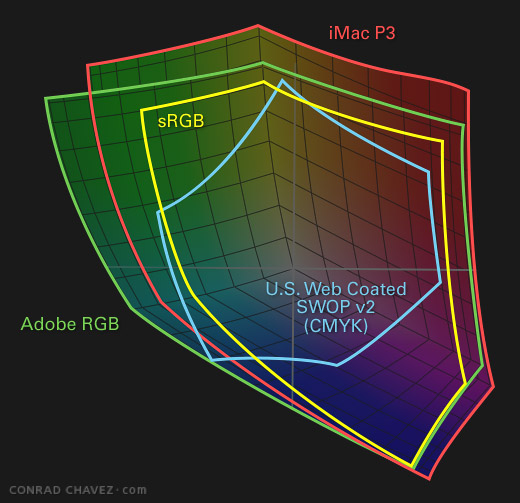

The key to this area is understanding the native gamut of the digital printing device. Not all are equal. Not all can match the litho gamut on coated papers; say a Fogra 39/51 based profile (such as ISO coated v2.icc). Most cannot run these brand colour(s) as a 5th or 6th special colour.

Most of the production toner based digital presses are CMYK, with some offering extra colours, such as white and clear toners. The colour gamut of these presses can be similar to offset litho, so will have the same issues with brand and PMS colour that cannot be achieved within their CMYK gamut.

HP Indigo’s can use extra colours for this purpose. Their IndiChrome off-press ink mixing system can give the special colour needed, using the 5th and 6th colour options, or extend the process color gamut by using their IndiChrome on-press 6 colour process method using CMYK plus orange and violet.

Inkjet devices have a very wide range of colour gamut’s, from smaller than a Fogra 39/51 based CMYK profiles, to approaching Adobe RGB 1998. This is because of the many inkjet technologies, applications, devises and the number of ink colours used. Each will have its own native colour gamut, based of the inks and technology used and the substrate needed.

The applications and markets that inkjet devices now cover many areas: POS, fine art, transactional and direct mail, packaging, labels, and increasing, general commercial printing. The devices to serve these many markets only share the wide term ‘inkjet’. The rest is market and product driven.

At one end the relatively slow 10 colour plus wide-format machines serving the proofing, photographic, short run POS and fine art (gilcée) markets. In addition to CMYK they will also have a selection from light CMY, RGB, green, orange and violet and mid and light black (greys). This will provide the largest gamut, close to some RGB colour spaces and cover up to 99% of Pantone colours, not of course the metallic and fluorescents.

At one end the relatively slow 10 colour plus wide-format machines serving the proofing, photographic, short run POS and fine art (gilcée) markets. In addition to CMYK they will also have a selection from light CMY, RGB, green, orange and violet and mid and light black (greys). This will provide the largest gamut, close to some RGB colour spaces and cover up to 99% of Pantone colours, not of course the metallic and fluorescents.

The faster, production wide-format inkjet machines are mostly based around CMYK and therefore will have a gamut similar to Fogra 39/51 on coated substrates. This will be dependent on the ink jet technology and ink type, solvent, eco-solvent, latex, UV etc. Each will have a differing colour gamut.

Then, of course we come to the latest continuous fed inkjet presses running at speeds of up to 150 meters per minute. Based on an average web width of 500mm or so, that equates to around 5000 perfected B2 sheets per hour.

Of course factors like resolution need to be taken into account. The highest resolution, say 1200dpi x1200dpi reduces the speed to around 60 meters per minute for most devices, giving a B2 sheet, perfected equivalent of 2000 sheets per hour.

These inkjet presses from manufacturer’s such as Ricoh, HP, Xerox, Cannon, KBA and Screen have been developed from the lower resolution continous feed inkjets for the transactional markets, then breaking into the book and direct mail areas. They now seem ready for parts of the demanding commercial printing market. Again all are based on differing inkjet head and ink technologies. All claim they will print on standard offset coated and uncoated papers, usually by pre-coating the paper. Others now have developed inks that can print on these papers without pre-coating

These inkjet presses from manufacturer’s such as Ricoh, HP, Xerox, Cannon, KBA and Screen have been developed from the lower resolution continous feed inkjets for the transactional markets, then breaking into the book and direct mail areas. They now seem ready for parts of the demanding commercial printing market. Again all are based on differing inkjet head and ink technologies. All claim they will print on standard offset coated and uncoated papers, usually by pre-coating the paper. Others now have developed inks that can print on these papers without pre-coating

These offer a range of colour gamut’s from US SWOP v2, smaller then a Fogra 39 based gamut, to larger than Fogra 39/51. All of these options need to be investigated in relation to the market and clients of an individual printer.

How important is the accurate reproduction of brand and special colour that could be outside of the gamut of the chosen press?

There are more specialised web fed inkjet press for the label market, usually with a very small web width and often combining other printing methods such as flexo and screen process which does address the issues with Pantone and brand colours. In addition finishing systems are often on-line, such as foiling and laser cutting.

Finally we come to the very high quality sheet fed inkjet area. These presses, often built on conventional sheetfed press ‘bodies’ with the inkjet technology replacing the offset litho printing units, are firmly aimed at the high end, short run commercial and packaging markets. The main players are Fuji, Konica Minolta and Heidelberg. Of course, we must consider Landa and their Nanography and in space too, as their technology is basically inkjet onto a continuous belt with then applies it, dry, to the substrate!

Finally we come to the very high quality sheet fed inkjet area. These presses, often built on conventional sheetfed press ‘bodies’ with the inkjet technology replacing the offset litho printing units, are firmly aimed at the high end, short run commercial and packaging markets. The main players are Fuji, Konica Minolta and Heidelberg. Of course, we must consider Landa and their Nanography and in space too, as their technology is basically inkjet onto a continuous belt with then applies it, dry, to the substrate!

Most of the above inkjet sheet fed presses claim a larger gamut then Fogra 39/51 for coated stocks. Most however do not provide any firm details on this increased colour gamut.

So just a brief overview of what many pundits in the printing industry consider to be the main printing method of the future, covering many markets at present served by sheet fed offset litho. At present inkjet cannot remotely approach the speeds of web offset or gravure presses, with their speeds of around 10 meter per second.

The main message is, if colour and the correct reproduction of brand colours are important to your market, research and testing is needed to be sure of the colour gamut of any digital presses you are considering cover your clients needs.

The main message is, if colour and the correct reproduction of brand colours are important to your market, research and testing is needed to be sure of the colour gamut of any digital presses you are considering cover your clients needs.

Twitter

- Paul Sherfield who runs the consultancy is well known in the printing and pre-media industry as having considerable knowledge on digital workflows, with a special expertise on the business reasoning behind such systems.

He has installed some of the most successful digital pre-press and pre media systems in the UK. For 2 years he worked on a number of medium term projects before starting the consultancy in July 2000. Before this he was a partner in what became one of the leading pre-press/printing companies in London.

He is active in a number of industry groups including the BPIF Technical Standards Committee, ISO TC 130 printing standards committees and is chair of the BPIF steering group for ISO 12647/2 UK certification, He is a regular speaker at seminars and conferences.