The Power of Grey and Black-updated 9/2017-UV curing and ink costs

Update 9/2017

With the increasing use of UV curing on sheet-fed offset litho presses, shown by the number of new installations and retro fits of UV curing to existing machines, the area covered below becomes very important and interesting due to the higher inks costs of the inks for all flavours of UV curing, H-UV, LE-UV, LED-UV etc.

With the increasing use of UV curing on sheet-fed offset litho presses, shown by the number of new installations and retro fits of UV curing to existing machines, the area covered below becomes very important and interesting due to the higher inks costs of the inks for all flavours of UV curing, H-UV, LE-UV, LED-UV etc.

The use of ICC CMYK profiles with lower TAC and higher GRC will reduce ink consumption by at least 10%. While is possible to use the ‘ink savings’ tools in CtP workflows, I feel the best solution is to use a ICC CMYK profile. Using the standard Fogra datasets or a dataset from a custom/client printing machine, by using the latest dataset optimisation tools together with the latest profile creation software will produce a very accurate profile offering all the benefits covered below. Since write the blog in March 2012 i have used these profiles, and other I have created myself for clients, on many occasions.

Apart from the ink savings, these profiles offer better stability on press, much less paper deformation on light weight paper and better drying. (When not using any drying systems.)

Please do contact me if you need any more information on how to implement these profiles for your workflow, presses and clients.

Some of the other colour geeks around will have been aware of the the recent work by VIGC, the Belgium printing industry research group, on ISO 12647/2 CMYK profiles with very low TAC (Total Area Coverage) and high levels of GCR (Grey Component Replacement).

Using the Fogra 39 and 47 datasets for coated and uncoated papers they produced a series of profiles with decreasing TAC and increasing GCR.

For each paper type there are 4 different TAC values 220%, 260%, 300% and 320%. The profiles were generated with X-Rite i1 Publish profiling software.

Some of these profiles look interesting, not to say challenging and radical, especially the 220% and 260% TAC version for coated papers.

I have been using Fogra 39 and 47 based profiles with GCR for differing needs; printing on lightweight coated papers, producing 4 colour black and white separations with a stronger black, so giving greater stability and neutrally on press; but have never ‘pushed’ the TAC and GCR boundaries into these areas!

So with the help of two long-standing clients, I decided to test the 220% and 260% TAC coated profiles against the ISO coated v2 profiles more commonly used.

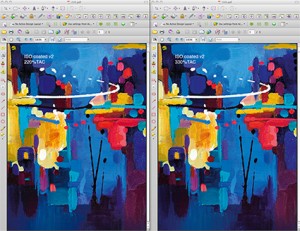

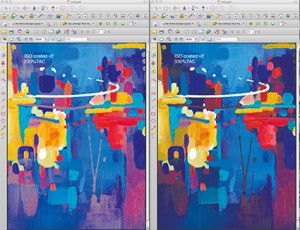

I created a A4 test page in Adobe InDesign, using ECIRGBv2 images and saved four PCF X1a files, using the 220% and 260% TAC profiles from VICG and two, more standard, ISO coated v2 profiles with 300% and 330% TAC.

The four pages were proofed at Bonhams the Auctioneers design and prepress studio in London, using an EFI XF colourproof rip running Epson Stylus Pro 7900 Spectroproofer printers with inline spectrophotometers and proof verification to ISO 12647/7.

The proofs were all verified and had an average De of 0.80 and a maximum De of 3.08.

When compared by a number of professional observers under controlled D50 lighting they could see no difference between the four test pages and profiles. Very impressive so far, and as VIGC reported.

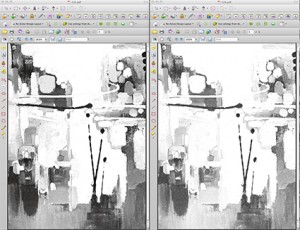

The four PDF X1a files were also ‘soft proofed’ on an Eizo ColorEdge CG243W monitor and again no difference could be seen. However, as would be expected, when looking at the separations the difference in the black ‘separation’ was marked!

Screen grabs for the separations:

The three screen grabs above show the CMYK results, the CMY separations and the black separation. The 220% TAC profiled image is on the left, the 330% TAC profiled image on the right.

So the next test had to be to print the four pages. While the digital contract proofs and the soft proofs showed that the four profiles give the same colour appearance I was uncertain how they would work on a litho press!

Would the lower ink film coverage on the 260% and 220% TAC effect the gloss of the printed result?

Witherbys/Lithoflow Printing, the oldest printer in London, dating back to 1740, but with technology firmly in the 21st century offered to help. They imposed the four test pages and imaged to plate via their Screen Trueflow CtP system using Spectra 2 XM screening.

The pages were printed together on a 6-colour Heidelberg 74 B2 press; the paper was Creator Silk 130 gsm. The printed sheets were controlled to ISO 12647/2 using Bodoni PressSIGN software. The printed sheets scored 96% using this software.

Visually, again the match between the four pages/profiles was perfect. There was little or no loss in gloss for the 220% or 260% TAC profiles when compared with the 300% and 330% TAC profiles.

Also the uncoated Fogra 47 based profiles should, on the basis of these tests, be very useful when using difficult uncoated stocks.

The use of these types of profiles seems extreme but on the evidence of this trail and VIGC’s own tests it is worth testing these profiles in your workflow. The gains in press colour stability, ink consumption, ink drying and less marking should be considerable. They are freely from the the VIGC website.

Links:

http://w3.efi.com/proofing-and-inkjet-production-solutions/product-overview/efi-colorproof-xf

http://www.epson.co.uk/Printers-and-All-In-Ones/Large-Format/Epson-Stylus-Pro-7900-SpectroProofer

http://www.screeneurope.com/ga_dtp/en

http://www.bodoni.co.uk/index.php?cPath=205&osCsid=1c39d0032d160af21fdee2c7cfeb49f6

http://www.witherbysonline.com

Twitter

- Paul Sherfield who runs the consultancy is well known in the printing and pre-media industry as having considerable knowledge on digital workflows, with a special expertise on the business reasoning behind such systems.

He has installed some of the most successful digital pre-press and pre media systems in the UK. For 2 years he worked on a number of medium term projects before starting the consultancy in July 2000. Before this he was a partner in what became one of the leading pre-press/printing companies in London.

He is active in a number of industry groups including the BPIF Technical Standards Committee, ISO TC 130 printing standards committees and is chair of the BPIF steering group for ISO 12647/2 UK certification, He is a regular speaker at seminars and conferences.